Grinding Mill Processing Plant. Grinder Process

Limestone mining process can be included into three steps, crushing, screening, and grinding. In the grinding limestone production line, we always use jaw crus Calcium Carbonate Powder Mill

www.netzsch-grinding.com - NETZSCH Grinding & …

For more than 50 years, NETZSCH has been one of the worlds leading suppliers of mixing and dispersing technology with its Grinding & Dispersing Business Unit. The special-purpose machine manufacturer produces several hundred dissolvers a year. These guarantee a high standard of quality and reliability in the production process. Read more ...

Milling & Grinding | Dinnissen BV

Roller mill. With a roller mill, a product is compressed and reduced between two counter-rotating rotating rollers. A major advantage of this process is that the proportion of fine particles (powders or dust) remains minimal compared to other grinding principles and that a nice homogeneous grain-size distribution is …

Outotec Grinding Mills - Outotec

Grinding mill process design. Choosing an appropriate grinding circuit configuration depends on your ore characteristics and mine plan. Outotec has extensive knowledge of comminution technologies and processes to ensure we provide the optimal solution for your needs.

Grinding Process - Mineral Processing & Metallurgy

Let us apply these ideas to the derivation of an equation for the rate of grinding in a mill. It follows that if, as appears reasonable, the change of specific surface S cm²/cm³, within a mill depends upon the diameter of the mill, upon the ball diameter and upon the mean diameter of the particle, D, d and b respectively, upon the density of the balls and the pulp, q and σ respectively, on ...

Ball Mill, Grinding Mill, Ball Mill Manufacturers, Ball ...

Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energy-saving ball mill up to 30%, great ball mill working principle, which greatly reduces the cost of …

Grinding Mill Design & Ball Mill Manufacturer

All Grinding Mill & Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum.

Post-Pre grinding - Van Aarsen | The vital link to …

Both the GD and 2D hammer mill series cover capacities ranging from 5 – 100 tons per hour, dependent on type of raw material, formula and required grinding structure and can be incorporated in a pre-grinding as well as a post grinding system as a complete grinding solution including pre-bin, feeder, magnet cleaner, hammer mill, discharge hopper, aspiration filter, fan and control system.

Making History - Grinding stone - YouTube

4-10-2009 · The Medieval process of grinding down stone so it can be made into bread.

Cement mill - Wikipedia

The grinding action employs much greater stress on the material than in a ball mill, and is therefore more efficient. Energy consumption is typically half that of a ball mill. However, the narrowness of the particle size distribution of the cement is problematic, and the process has yet to receive wide acceptance.

HCM Grinding Mill - Raymond Grinding Mill, …

Grinding Equipment. HCH Ultra-fine Grinding Mill for Preparation of Petroleum Coke Powders HCH Ultra-fine Grinding Mill for Preparation of Petroleum Coke Powders ; The Process of Special HLM Superfine Vertical Grinding Mill for the Factory of Slag Powder The Process of Special HLM Superfine Vertical Grinding Mill for the Factory of Slag Powder

Grinding mill | Palamatic Process

The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products. Common applications involve the fine grinding of sugar, salt, sodium bicarb, etc. The average achievable particle size range of the pin mill is around a d50 of 80 microns.

cement grinding mill process - azdoc.nl

Cement Grinding Plant Fote MachineryFTM. Aug 08 2019 · Cement ball mill is the key equipment in the cement grinding process FTM cement ball mill adopts high chromium alloy steel or double medium quenched steel liner which has the characteristics of high quenching hardness and high toughness The wear in production is small The milling form of open flow provides a strong guarantee for the

Grinding mills - for mining and minerals processing …

Every mining operation has a unique grinding process. liming has experience of over 8,000 grinding mills globally, including manufacturing and delivering the largest SAG/AG mills in the world. Our experts welcome the opportunity to assist you with circuit and circuit control design as well as start-up, operation, and optimization of your mill.

Granulation Grinding Cone Mill Machine from …

15-4-2019 · For granulation applications - the Kemutec KEK Grinding Cone Mill is recognised as one of the most versatile size reduction grinding mill machines in the stone and powder processing industry.

Particle Size Reduction Equipment from Union …

Union Process manufactures a broad line of particle size reduction equipment such as wet and dry grinding Attritors and small media mills, in laboratory and production sizes. Our particle size reduction equipment is customizable to meet your specific milling and dispersion needs.

powder grinding mill ball mill and process of …

Powder grinding plant process introduction: Grinding system composed with jaw crusher, bucket elevator, electromagnetic feeder, grinding unit, blower, analyzer, cyclone powder collectors, bag filters, pipes and electrical cabinet parts. According to customer demand can adopt Raymond mill, YGM high pressure grinding mill,,HGM micro powder. Get ...

Process Of Grinding In Ball Mill - ttmteak.nl

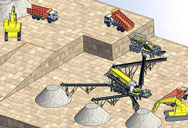

Mill Process - Grinding Mills - miningsurplus.com. Mill Process - Grinding Mills. Grinding Mills also know as Semi-Autogenous (SAG), Ball or Regrind Mills are used in the primary or early stages of pulverizing the ore in the process plant. This initial grind of the ore is typically completed in two or three stages.

Cement Grinding Mill Process - claudiadesign.nl

Cement Grinding Mill Process. Cement ball mill can not only dry production but also wet production, grinding and drying at the same timeement mill is mainly used in building materials, metallurgy, power and stone industries, grinding all kinds of cement clinker and other materials.