Coal Grinding - Cement Plant Optimization

Most commonly used mills for coal grinding in cement plants are closed circuit air swept (Single chamber) ball mills and vertical mills. Ball Mill: Single chamber ball mills (with classifying liners and dam ring) with drying chamber and static or dynamic separator are commonly existing for coal grinding in cement plant for one or more kilns as per capacity.

Coal Grinding Mill Plant

Coal Grinding Mill Plant Coal grinding mill plant is a crucial additional devices pertaining to coal-powder furnace, there are 3 solutions to break the actual coal group along with mill these directly into natural powder,it is actually crushing, impacting and even grinding.

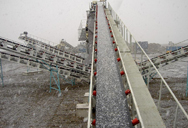

coal grinding mill plant for coal grinding process

Coal mill is an important auxiliary equipment for coal-powder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding. Air swept coal mill is the main equipment in cement plant for both drying and grinding of the powders.

Mobile grinding plant for solid fuels

Loesche builds coal grinding plants for a throughput of 2 t/h to 300 t/h and is the market leader in the sector of self-inert, central coal grinding plants for hard coal and the grinding of brown coal in verti- …

Grinding plant - Fives in Cement | Minerals

Material drying is achieved with Pillard HeatGen Systems, delivering the necessary hot gases to the grinding plant, capable of firing liquid, gaseous or pulverized solid fuels such as coal and pet-coke.

How A Coal Pulverizer Works - Coal Grinding Process | 3D ...

Feb 23, 2010 · Here’s a 3D animation of how a coal grinding system works. Williams Crusher has the most advanced direct fired coal and stone coke pulverizing system in the field today.

Coal Mill_Coal Grinding Mill_Coal Grinding Machine-Vipeak ...

Coal dust is a type of fine coal powder ground by coal grinding mill, size range 0.05~0.01mm, and most of powder’s size range 20~50μm. Pulverized coal processed by Vipeak grinding machine could be fully burned, use ratio very high, and we have provided technical support for many power plant.

What is the most appropriate grinding mill type for coals ...

The layout of a coal grinding system must take into account the available heat sources for drying the raw coal as well as the fire and explosion hazards of coal and coal dust. The entire grinding plant must therefore be shock-resistant and equipped with a number of explosion relief valves. When grinding low-explosive...

Grinding Mill For Coal Fired Power Station

Coal mill in the power plant. Coal power plant grinding mill yogamayacomfortsin coal grinding mill in power plant coping with coal quality impacts on power plant operation and maintenance but does not change the fundamental capacity of the 247 online flexible operation of coalfi.

Coal crusher machine,coal grinding mill plant, mobile coal ...

Coal Ball Mill machine is an important auxiliary equipment for coal-powder furnace, and it has three methods to crush the coal lump and grind them into powder,like crushing, impacting and grinding. Air swept Coal Ball Mill is the main equipment in cement plant for both drying and grinding of the powders.

Working Of Vertical Coal Mill For Cement Grinding Plant

Vertical coal mill working used in cement plant The Mobile Cone Crusher plants vertical coal mill working used in cement plant About Vertical Roller Mill In . More Cement mill Wikipedia the free encyclopedia A cement mill or finish mill in North American usage is the equipment used to grind the hard nodular clinker from .

THE COAL GRINDING - energosteel.com

Jul 11, 2017 · Fuel drying and fuel grinding can be carried out separately or jointly in one unit. If these processes occur separately, then coal dried in drying drums and ground in short ball mills. The ratio of drum length to the drum diameter is usually 1.5: 1. The 40 mm grinding balls of the 2nd and the 3rd hardness groups have used for coal grinding at thermal power plants in USSR.

grinding mill coal australia - fitboxpercani.it

Grinding trends in the cement industry 1 Tilbury grinding plant, owned by Cemex UK (Cemex) 2 Mill orders 2007/2008 according to mill types (OneStone) [3] Bowl mills for coal power - GE Power & Water SM bowl mill: This modern air swept vertical mill represents the very latest design and technology innovations in the pulverising industry.

2nd Hand Coal Grinding Mill Sale – Made in China

Coal Mill Price New And Second Hand Coal Mill Price . coal ball mill machine YouTube. Dec 21, 2016 183; A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. Jul 02, 2015183; grinding plant for sale used second hand ball mill , 2nd Hand Sewing Machine For Sale In Chennai , Peralatan Penggiling

ATOX coal mill - FLSmidth

ATOX coal mill. Working principles The raw coal enters the mill via a rotary sluice and feed chute and is discharged onto the rotating grinding table. The rotation of the table accelerates the flow of material towards the grinding track, where the coal is ground between the table and the three rollers. The coal then continues over the dam