Electrical Maintainance Of Cement Production …

Electrical Maintainance Of Cement Production Equipment. A 6 week modular course exploring the maintenance of cement factories including the different maintenance challenges faced by different cement factories around the world the assessment of cement manufacturing equipment condition common maintenance and rel,Electrical Maintainance Of Cement Production Equipment..

Electrical Maintainance Of Cement Production …

Maintenance Of Equipments Used In Cement Production. Electrical maintainance of cement production equipme Machinery and equipment used on cement plants and their role. • Advanced techniques and tools for electrical maintenance, control systems as . Get Details; Electrical Machinery For A Cement Equipment. GREAT SUCCESS MACHINERY ELECTRICAL CO., LTD.-Cement Also, …

Electrical Maintainance Of Cement Production …

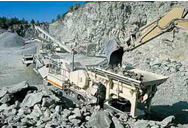

Electrical Maintainance Of Cement Production Equipment. We are a large-scale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment. And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, …

Maintenance Of Equipments In Cement Production

Electrical Maintainance Of Cement Production. Ltd. TDFB is a professional company for maintenance of cement production lines. Read more. cement plant maintenance stone in United Arab Emirates careerjet.ae. This position will be responsible for performing Electrical Instrumentation Knowledge of cement plant equipment maintenance hydraulics belt ...

electrical maintainance of cement production …

electrical maintainance of cement production equipment. Up-to-date with electrical equipment Qassim Cement line 1 ... - Abb . Qassim Cement line 1 upgrade and line 3 total electrification. Reprint from ... QCC started its first production line in the 1970s, using electrical equipment supplied by ABB. The .... Operators and maintenance engineers supplied by the client. Read more---Tangshan ...

IMPROVING THERMAL AND ELECTRIC ENERGY EFFICIENCY AT …

Improving Thermal and Electric Energy Efficiency at Cement Plants: International Best Practice 1 Cement production is a resource-intensive practice involving large amounts of raw materials, energy, labor, and capital.

Energy efficiency in cement manufacture - VDZ

Second, electrical energy is used to operate various units – in particular raw material and cement grinding systems. Today, electrical energy consumption in cement works makes up over 10 per cent of the total energy consumption, with the energy costs being split almost equally between fuel and electricity. In total, the German cement industry used 96.0 million gigajoules of fuel in 2018, whilst electricity consumption …

Reduce Energy Consumption: Cement Production

A China-based cement plant used VFDs to significantly reduce its energy consumption in its dry-process kilns, responsible for production of 1.4 million tons of cement each year. Traditional damper control systems used a fixed amount of energy, so fans at the plant always ran at full capacity even when the facility wasn’t producing product—wasting energy and causing unnecessary wear on the ...

Electrical equipment check list in cement industry

Electrical equipment check list in cement industry Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including, Electrical equipment check list in cement industry, quarry, aggregate, and different kinds of minerals. We can provide you the complete stone crushing and beneficiation …

Best energy consumption - International Cement …

Typical cement plant power costs can range from EUR39 to EUR170/MWh. Mill designs. The most important first step in controlling energy consumption is to be aware of the relative importance of the process areas where most energy is consumed. Figure 2 shows a typical breakdown of electrical energy consumption at a cement plant. The most obvious area for attention is that of grinding, both raw and cement…

Critical Equipment Maintenance

Critical Equipments. This type of maintenance policy and strategy will improve performance of CHP through availability of Critical Equipment. The concept of Maintenance Method for Critical Equipments (MMCE), discussed in this stone for Coal Handling Plant is to offer significant benefits. The major coverage on bearings and gearboxes of Critical Equipment condition monitoring is featured in ...

499-1989 - IEEE Recommended Practice for …

A recommended practice for electric drives and related electrical equipment for installation in the cement industry is set forth. The recommendations apply to all electric drives and include motors, controls, and control wiring associated with machinery or equipment commonly used in the manufacturing areas of cement plants, but they do not apply to power distribution circuits.

Cement | Market-specific Solutions | Siemens Global

Our portfolio covers the delivery and installation of electrical equipment and integrated solutions including design, planning, engineering, project management, manufacturing, installation, testing and commissioning. Furthermore, training, after-sales services and maintenance are among the many customer services Siemens provides.

FOR CEMENT INDUSTRY - indiaenvironmentportal

Table 3-2: Total Cement Production from 2006-08..... 3-3 Table 3-3: Raw Material Consumption of Cement..... 3-7 Table 3-4: Thermal and Electrical Consumption in Dry Process Cement Plants in India..... 3-8 Table 3-5: Specific Thermal Energy Consumption in Indian Cement Sector..... 3-8 Table 3-6: Specific Electric Energy Consumption (kWh/t of Material)..... 3-8 Table 3-7: Sources of Fugitive ...

Electrical Maintenance Engineer Resume Samples …

Organized and handled required electrical activities on six CSD/water production lines and their utilities which reduced electrical down time by 41% of total efficiency & improved productivity by 56%.

): Automation solutions for the Cement Industry.

of sulfates. Cement plants can operate continuously for long time periods (i.e., 6 months) with minimal shutdown time for maintenance. Air pollution problems related to the pro-duction, handling, and transportation of Portland cement are caused by the very fine particles in the product. The main stages of cement production at a Portland cement ...

Shut down management - Plant Maintenance

Shut down management For Coal handling plant of thermal power station –A New Approach By Makarand Joshi 1.0 Abstract: - Shut down can be defined as scheduled down period for a plant for scheduled maintenance for an extended period of time. Shutdowns provide unique opportunities to a maintenance department not normally available during standard operation or even during short …