Vanadium processing | Britannica

Vanadium is extracted from carnotite as a coproduct with uranium by leaching the ore concentrate for 24 hours with hot sulfuric acid and an oxidant such as sodium chlorate. After removal of solids, the leachate is fed into a solvent extraction circuit where the uranium is extracted in an organic solvent consisting of 2.5-percent-amine–2.5-percent-isodecanol–95-percent-kerosene. Vanadium ...

Vanadium Ores | Article about Vanadium Ores by …

Vanadium Ores mineral formations containing vanadium in amounts sufficient to make extraction of the element by modern methods economically feasible. The most important vanadium-ore minerals are vanadinite (19 percent V2O5), descloizite (22 percent), cuprodescloizite (17-22 percent), carnotite (20 percent), roscoelite (21-29 percent), and patronite (17 ...

Vanadium Extraction Process - Mineral Processing …

The extraction and recovery process of vanadium as a by-product from the tailings of a uranium processing plant poses many problems. In this study vanadium is recovered from impounded resin-in-pulp tailings and from the current tailings of a uranium plant which did not include a circuit for vanadium recovery in its initial design. Since the vanadium content is quite low, capital expenditures ...

Vanadium & Uranium Extraction

The vanadium extraction was 92 pct under these conditions. The best salt roast-leach results on the low-grade ore were obtained with a 4-hr roast at 800° C with 10 pct salt followed by an 18-hr leach at 80° C and 300 lb/ton H2SO4. The vanadium extraction was 88 pct under these conditions.

Making Vanadium | Vanitec

Titaniferous magnetite ore is mined in South Africa and China and processed for vanadium extraction. Tianiferous magnetite ore is also processed in steelmaking operations in China, Russia and South Africa. A duplex BOF process in the steelmaking shop yields a vanadium rich slag that can be converted into V2O5 via hydrometallurgical processing. Vanadium is present in crude oil in the Caribbean ...

HIGH VANADIUM EXTRACTION CONFIRMED AS …

performance, vanadium extraction, reagent usage and operating conditions for the Grate Kiln pilot testing scheduled at liming in quarter 1 and 2 of 2020. Results of the bench-scale testwork show: • High quality pellets, with the mechanical strength required to survive the roasting process, can be produced without additional binders or processing steps. • Vanadium roast leach extraction was ...

Processing of vanadium: a review - ScienceDirect

Apart from titanomagnetite and ilmenite ore deposits containing vanadium, slags from the ferrous industry are a major source of supply. At present, known world reserves are expected to supply the next century’s needs. Vanadium-bearing materials are treated by means of several processes such as calcium reduction, roast/leach, solvent extraction and ion exchange to recover vanadium either as ...

Extracting Vanadium Through Heap Leach …

Standard black shale processing scheme is to mine the ore, crush it, grind it, filter it, roast the ore with salt and sulfuric acid (about 200 lbs per ton acid consumption versus the 70 lbs per ton that Prophecy’s Gibellini uses), tank leach the ore, do a liquid- solid separation of the solution from the ore, recovery the vanadium by solvent extraction, precipitate an ammonia compound and ...

Extraction of vanadium from direct acid leaching …

Solvent extraction of vanadium from a direct acid leaching solution, generated by the direct leaching of clay vanadium ore, was conducted using tertiary amine N235, and the effects of the main factors on the extraction of vanadium and iron were investigated. Through a three-stage countercurrent extraction under the following optimum conditions: N235 concentration of 10% (v/v), initial aqueous ...

(PDF) Vanadium extraction from magnetite ore …

Vanadium extraction from magnetite ore using alkaline roasting and acid leaching processes: optimization of parameters by response surface methodology February 2019 DOI: 10.22044/jme.2018.7578.1610

Efficient Extraction of Vanadium from Vanadium–Titanium ...

the vanadium extraction from the vanadium–titanium magnetite concentrate. At the same time, phase transformation analyses were conducted to reveal the mechanism by which potassium salt strengthens the vanadium extraction and the kinetics model was established to further explain the effect of potassium salt. 2. Experimental 2.1. Materials The vanadium–titanium magnetite ore used in the ...

(PDF) Extraction of Titanium and Vanadium by …

Extraction of Titanium and Vanadium by Chloride Leach Processes . Conference stone (PDF Available) · May 2012 with 980 Reads How we measure reads A read is counted each time someone views a ...

AVL Achieves Vanadium Extraction Process …

Australian Vanadium Limited (AVL) has successfully trialled an innovative process to improve vanadium extraction, which achieved 95.5 per cent extraction rates. The resource company will now commence a detailed pilot scale test program as part of its aim to become a world-leading producer of the resource. “AVL is increasing its competitive advantage through process innovation. Our vanadium ...

Leaching For Vanadium Ore Professional

Vanadium Ore Processing. Vanadium ore processing, process crusher, mining equipment , vanadium ore processing 84 views the liming is the professional mining equipments manufacturer in the world, located in china,india, along with other asian et price vanadium ore processing mobile crushers all over the worldanadium ore.

First Vanadium Corp. - Home

First Vanadium’s Carlin Vanadium Project is located within Carlin Gold Trend – one of the world’s most desirable, favourable and prolific gold mining trends - where an untested high-caliber high-grade Carlin-style gold target has been recently interpreted on the Project by a renowned Nevada gold specialist and proven mine finder. This will be the near-term exploration focus. The Project ...

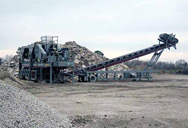

vanadium ore processing equipment - …

mineral processing equipment for vanadium ore in australia Vanadium Extraction Process Mineral Processing amp Metallurgy The extraction and recovery process of vanadium as a by product from the tailings of a uranium processing plant poses many problems. Large Output Vanadium Mining Plant in South Africa . After processed vanadium ore has a wide range of purposes in the industry mainly used …