Forces in a Cone Crusher | SpringerLink

21.03.2019 · The literature on the design of cone crushers and analysis of the corresponding crushing processes is mainly based on empirical observations. As a result, it is generally accepted that the crushing action is due solely to compressive forces. Crushers are designed on that basis. Accordingly, many cone crushers today are characterized by common operating principles.

Cone Crusher - an overview | ScienceDirect Topics

The cone crusher is a modified gyratory crusher, and accordingly many of the same terms including gape, set, and throw, apply. ... They are classified as jaw, gyratory, and cone crushers based on compression, cutter mill based on shear, and hammer crusher based on impact. A jaw crusher consists essentially of two crushing plates, inclined to each other forming a horizontal opening by their ...

Crushers - an overview | ScienceDirect Topics

They are classified as jaw, gyratory, and cone crushers based on compression, cutter mill based on shear, and hammer crusher based on impact. A jaw crusher consists essentially of two crushing plates, inclined to each other forming a horizontal opening by their lower borders. Material is crushed between a fixed and a movable plate by reciprocating pressure until the crushed product becomes ...

Cone Crushers | McLanahan

Cone Crushers. A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel. Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point. As the wedge or eccentric rotates to cause the compression within ...

Cone Crushers - Mineral Processing & Metallurgy

Cone Crushers. The Symons Cone Crusher has come into almost universal use during the last few years for the final stage of crushing. It is a development of the secondary gyratory crusher, which is merely a small gyratory crusher designed to break the product of the primary machine down to about 1½-in. size ; but the main shaft of a cone crusher instead of being suspended from a spider is ...

New and Used Cone Crushers for Sale | Savona …

Cone crushers are used in large primary ore crushing, secondary, and tertiary fine material as well as complete aggregate cone crushing lines. We also have cone crusher parts for sale but they are subject to availability. With the rapid development of mining technology, the primary cone crusher can be divided into four types: compound cone crusher, spring cone crusher, hydraulic cone crusher ...

C2R Cone Crusher - McCloskey International

The McCloskey C2R recirculating cone crusher combines the productivity of the 38″ cone with the versatility of a full screening and recirculating system, allowing operators to produce a high quality crushed and screened final product with one machine. The C2R cone crusher distinguishes itself as an entry-level cone with full level features like an anti-spin […]

Cone Crushers Designed for Material Processing | …

The Powerscreen® 1500 Maxtrak cone crusher is one of the largest mobile cone crushers available on the market. Specifically developed for users requiring higher tonnage, the plant can accept an all in feed from a primary crusher to produce large volumes of aggregate. With the Powerscreen® 1500 Automax® cone crusher, operators benefit from hydraulic overload […]

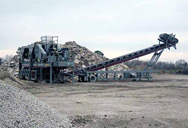

Crushers - All crusher types for your reduction …

Cone crushers . Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages. Sometimes, however, the stone size of the processed material is small enough by nature and the traditional primary crushing stage is not needed. In these cases, also cone crushers can carry out ...

Cone Crusher, Cone Crushers, Manufacturer, …

Akashganga Cone crushers are based on first class design technology and product development. As a result, our cone crushers are having outstanding features, which make our cone crushers to operate efficiently. The main shaft is of over size and is made of special alloy steel having high fatigue life. The floating design of shaft ensures reliability. The hydraulic system with nitrogen ...

Industrial Solutions Kubria cone crushers

cone crushers Cutting-edge technology in hard rock crushing Industrial Solutions. Our solutions for the hardest stone Fields of application and design characteristics Cost-efficient and versatile, these machines for crushing hard rock are available as either coarse, intermediate or fine crushers. Depending on the material to be crushed and the desired product size, thyssenkrupp cone crushers ...

DEM Modelling and Simulation of Cone Crushers and High ...

grinding circuits based on large inefficient tumbling mills. Circuits using Cone Crushers and High Pressure Grinding Rolls (HPGR) have proven to be more energy efficient. These comminution devices have during the last two decades been implemented for hard rock materials. These machines are hence suitable subjects for further performance ...

liming® GP7™ cone crusher - liming

As with all liming® GP Series™ cone crushers, liming® GP7™ is delivered with all tools required for safe maintenance work. The process control is based on advanced liming IC automation that provides easy, safe, and trouble-free operation. How others have improved profitability and reduced risks? View all customer cases. liming® GP7™ cone crushers technical specifications ...