Beneficiation Process of Kaolinite Clay: Kaolin Processing

Beneficiation Process of Kaolinite Clay and Kaolin Processing Production advantages are that the process uses conventional equipment and ordinary flotation reagents. Minerals such as calcite, fluorspar, silica, barite, sulphur, etc., are possible carriers.

Kaolin Beneficiation Process,Kaolin Beneficiation Plant ...

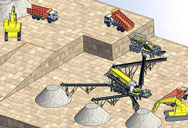

The processing technology of kaolin ore depends on the nature of the ore and the end use of the product. There are two kinds of dry process and wet process used in industrial production. Usually, hard kaolin is produced by dry process, and soft kaolin is produced by wet process. Dry beneficiation …

Kaolin Beneficiation Technology and Process Flow

Kaolin Beneficiation Technology and Process Flow For the separation of kaolin in the quartz, feldspar, mica, iron minerals, titanium minerals such as clay minerals and organic matter, produce kaolin products to meet the needs of various industrial sectors, in addition to the re-election, flotation.

kaolin beneficiation technology and process flow,kaolin ...

Kaolin Beneficiation Technology and Process Flow For the separation of kaolin in the quartz, feldspar, mica, iron minerals, titanium minerals such as clay minerals and organic matter, produce kaolin products to meet the needs of various industrial sectors, in addition to the re-election, flotation, magnetic separation of kaolin purified impurity, and sometimes stone bleaching, ultra-fine ...

Beneficiation and Evaluation of Mutaka kaolin

Kaolin is an important industrial mineral which often needs upgrading for special applications. The upgrading process, commonly known as beneficiation, is aimed at removing impurities like feldspar, quartz, iron oxide, etc.

evaluation and beneficiation of kaolin

kaolin beneficiation method . kaolin beneficiation method from large primary jaws and gyratories to cones and vsis for tertiary and quaternary finishing, methods of beneficiation kaolin clay Method of dry beneficiation of kaolin, comprising The invention relates to the field of ceramic industry and is a method of bleaching clay-containing

beneficiation techniques of kaolin - woningbedrijfwarnsveld.nl

methods of beneficiation kaolin clay . Method For Beneficiation Of Kaolin Kaolin Beneficiation Technology and Process Flow. Kaolin Beneficiation Technology and Process Flow For the separation of kaolin in the quartz, feldspar, mica, iron minerals, titanium minerals such as clay minerals and organic matter, produce kaolin products to meet the needs of various industrial sectors, in addition to ...

method for beneficiation of kaolin

kaolin beneficiation process De Balans. Method For Beneficiation Of Kaolin. Kaolin beneficiation process mainly adopts gravity separation to remove sand and classifying method, assisted by high gradient magnetic separation, carrier flotation, selective flocculation, stripping, stone bleaching and other methods, iron removal process is an important link of kaolin processing.

Mineralogical characterization and beneficiation study of ...

beneficiation plants. This situation and the rising costs of kaolin beneficiation in Brazil [8] indicate the need for further studies about the characteristics of kaolin and analysis of beneficiation to find more suitable treatment methods. This work reports the mineralogical characterization and

Kaolin Flotation: Beyond the Classical

There are several beneficiation techniques, such as size classification methods, magnetic separation, flotation, selective flocculation, and bleaching, which are used in the kaolin industry for removal of colored impurities that result in improving the brightness of kaolin.

INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY …

physical methods are froth floatation, gravity and magnetic separation, reductive roasting, size reduction by hydro cyclone, selective flocculation and acid treatment/leaching [10],[11],[12],[13]. The preferred beneficiation methods of kaolin minerals depend on the amount and nature of the mineral impurities associated to it. Although these methods

Kaolin - an overview | ScienceDirect Topics

Physicochemical methods of clay beneficiation for removal of impurities such as iron and titanium oxides are high-intensity superconducting magnetic separation, froth flotation, stone treatment using hydrosulfides to reduce and solubilize iron oxides, wet high-intensity magnetic separation, iron leaching by oxalic acid, selective flocculation, reductive leaching, and dewatering.

Methods for kaolin beneficiation - Henan Mining Machinery ...

kaolin is diluted and then degritted by passing it through a sandbox to remove coarse particles such as sand and mica After degritting the clay is ready for beneficiation In the industry beneficiation refers to removal of fine particle size impurities from kaolin that remain even …

GENESIS AND MORPHOLOGY OF IRON SULFIDES IN GRAY …

kaolin deposits may prove to be valuable kaolin re- serves should methods of beneficiation be developed. The size, morphology, and compactness of sulfides in gray kaolins are therefore important variables in the design of beneficiation techniques. The physical prop-

Beneficiation and mineral processing of clay minerals

Mar 23, 2016 · Flow Sheet for Beneficiation Process of kaolin Wet Screening Apron Drying Rotary Vacuum Filtration Raw Clay (1 ton) Slurry Tank Car Hopper Car Box Car or Truck Bagging Calcining Klin Water (4 tons) Portable Blunger Grit Grit Pump Calcined stone Leaching or Magnetic Separation Surface Modification Spray Dryer Centrifugal classification Slurry ...

Investigation on a gray kaolin from south east India ...

1. Introduction. Kaolin or china clay is one of the most versatile industrial minerals with wide range of applications. High value addition is achieved when the processed clay finds application as pigment in stone and paint industries (Murray, 1986).Kaolinite Al 2 Si 2 O 5 (OH) 4 is the principal mineral in kaolin and is made up of alternate octahedral gibbsite and tetrahedral silica layers ...

Reduction of Titanoferrous Impurities from Kaolin by ...

Conventional beneficiation methods used in kaolin processing are de-gritting, classification and sodium dithionite bleaching, which improves the optical properties of kaolin, wherein reduction of color imparting constituents such as Fe 2 O 3

(PDF) Characterization, beneficiation and utilization of a ...

The purified kaolinite and its SDS intercalate were characterised using techniques such as X-ray powder diffraction (XRD), X-ray fluorescence (XRF), thermogravimetric analysis (TGA), attenuated ...