Iron Ore Sintering Process in Steel Manufacturing

Sintering Process Equipment Used in Iron and Steel Manufacturing. Iron Ore Sintering Process in Steel Manufacturing ... Sinter is created by mixing iron ore concentrate with several additives such as limestone and silica to control the chemistry and then igniting it at 1200°C in a continuous belt-fed furnace. Sinter feed composition control is important because the various sinter feed ...

Manufacturing Process Of Sinter From Iron Ore Dust

The Sintering Process of Iron Ore . sinter During the sinter production process fine sinter is produced that . of Iron Ore: Iron Ore Fines/blue dust cannot be . Get Price And Support Online THE PERFECT SINTER PLANT SOLUTIONS FOR .

Sintering A Step Between Mining Iron Ore and …

Manufacturing process of sinter from iron ore dust. Iron ore mining process sintering mine equipmen The raw materials used in the iron ore sintering process are obtained from several sources like iron ore mining sinter feed dust recycling within the steelworks Iron Ore Sintering Hatch Sinter plant operators are under pressure to support a high production Oline Chat

Sintering: A Step Between Mining Iron Ore and …

Sintering: A Step Between Mining Iron Ore and Steelmaking By Alison Cestari 06.11.2019 The USGS defines iron ore as a mineral substance which, when heated in the presence of a reductant, will yield metallic iron (Fe).

Iron Ore Sintering Process in Steel Manufacturing

Gain economic benefits for the iron ore sintering process and the blast furnace with the Thermo Scientific CB Omni Fusion Online Elemental Analyzer configured for the sinter feed application. stone composition is one of the most important parameters for the efficiency of the sinter process. The CB Omni analyzer for sinter measures sinter feed chemistry on-line and provides minute by minute ...

Modeling Sintering Process of Iron Ore - IntechOpen

wide extent, from iron ore to dust recycling and fluxing agents . The natural resources of iron ores varies widely depending on the mineral composition and mining technology applied to produce the sinter feed. Therefore, it is of special importance to developed comprehensive tools to draw good decision on what kind of available raw materials and their blending will meet the sinter quality ...

The Sintering Process of Iron Ore Fines – IspatGuru

Sintering is a thermal process (carried out at 1300 deg C to 1400 deg C) by which a mixture of iron ore, return fines, recycled products of the steel plant industry (such as mill scale, blast furnace dusts, etc.), slag forming elements, fluxes and coke fines are agglomerated in a sinter plant with the purpose of manufacturing a sintered product of a suitable stone composition, quality ...

What Is Iron Ore Sintering? (with pictures)

02.04.2020 · Other iron ore sintering processes use machines that take crushed iron ore and mix it with water and other substances, known as fluxes, prior to igniting the mixture. Electricity is conducted through the mixture, and its surface is ignited to help form an agglomerate. Dust from the iron ore, as well as iron particles that do not meet size requirements, are recirculated through the machine …

Sinter plant - Wikipedia

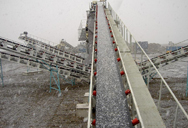

Sinter plants agglomerate iron ore fines (dust) with other fine materials at high temperature, to create a product that can be used in a blast furnace. The final product, a sinter, is a small, irregular nodule of iron mixed with small amounts of other minerals. The process, called sintering, causes the constituent materials to fuse to make a single porous mass with little change in the stone properties of the ingredients. The purpose of sinter are to be used converting iron into steel.

CHAPTER-11 FUNDAMENTALS OF IRON ORE SINTERING

CHAPTER-11 FUNDAMENTALS OF IRON ORE SINTERING R. P. Bhagat INTRODUCTION The process of sinter making originated from a need to make use of fines generated in mines and in ore benefiCiation plants. With the development of sintering technology, a sintering plant has become a tremendous success for providing a phenomenal increase in productivity and saving in coke rate to …

(PDF) Iron Ore Sintering: Process - ResearchGate

The process has been widely studied and researched in the iron and steelmaking industry to know the best parameters that allows for obtaining the best sinter quality. The present stone reviews the ...

Recycling of Blast Furnace Dust in the Iron Ore …

In iron ore sinter plants blast furnace dust and other fine-grained residues which are rich in iron or carbon content are recycled. The carbon contained in the blast furnace dust can be used to replace coke breeze which is added to the charge as fuel for the sintering process. However, there is no information in the literature on the carbon replacement factor of fine-grained blast furnace dust ...

Sinter Quality and Process of Sintering Iron Ores – …

Sintering process is a generic term that is used to describe the process of agglomeration of a green mix of iron ores, fluxes and coke and plant solid wastes having a particle size of -10 mm so as to produce sinter which can withstand operating pressure and temperature conditions existing in a BF. Solid wastes such as dusts, sludges, slags and mill scales etc. are used for their utilization in ...

Visit of Iron Pellet Manufacturing Plant - YouTube

20.03.2017 · This video is for educational purpose (Gurukul Section of our channel). We described here about the process of manufacturing of iron pellets - raw material for making steel. We have given an ...

Iron Ore Sintering: Process - researchgate.net

Iron Ore Sintering: Process D. Fernández-Gonzáleza, I. Ruiz-Bustinza b, J. Mochón , C. González-Gascac, and L. F. Verdejaa aDepartment of Materials Science and ...

sinter ore process - communales2018.be

12.5 Iron And Steel Production US EPA. 12.5.1.1 Sinter Production The sintering process converts finesized raw materials, including iron ore, coke breeze, limestone, mill scale, and flue dust, into an agglomerated product, sinter, of suitable size for charging into the blast furnace.

PROCESS BRIEF - Ministry of Steel

dust, smoke, noise, heat & gas etc. 2. SCOPE This code of safety is applicable to Sinter manufacturing plant as well as Sinter Plant Dept.of an Integrated Steel Plant. 3. PROCESS BRIEF Sintering process is developed mainly to utilize under size of lump ore called iron ore fines; which otherwise, could not be charged directly in blast furnace. In

Maximizing high Alumina Iron Ore fines …

The main objective of this project is to maximize the available Low Grade high alumina Iron Ore fines at economical price in Pig iron manufacturing process through better process optimization & thereby achieving lowest cost of production.. Sinter plants agglomerate iron ore fines (dust) with other fine materials at high temperature, to create a product that can be used in a blast furnace.

Agglomeration Process in English - YouTube

12.11.2015 · P-SCA for use in blast furnace has been developed with Indian iron ore to utilize the micro-fines in sintering. P-SCA can replace usual sinter/pellet in blast furnace. It is energy efficient process.