Jaw Crushers - high quality and reliability from …

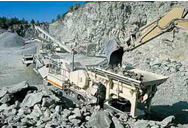

Jaw Crusher technology RETSCH Jaw Crushers are robust and powerful forced-feed crushers. The feed material passes through the no-rebound hopper and enters the crushing chamber. Size reduction takes place in the wedgeshaped area between the fixed crushing arm …

jaw crusher reduction ratio - watervrienden …

Jaw Crusher Reduction Ratio, Wholesale Various High Quality Jaw Crusher Reduction Ratio Products from Global Jaw Crusher Reduction Ratio Suppliers and Jaw Crusher Read More Sturtevant manufacturers jaw crushers and many other types of Learn more about the Jaw Crusher by clicking on Up to 8:1 material reduction ratio Applications.

Jaw Crusher Size Reduction Ratio – Made in China

The reduction ratio for jaw crushers range from 3/1 to 5/1. Get Price. Crushers in Cement Industry - Scribd. The main purpose of a crusher is the size reduction of the feed. step of the ore concentration process, the selection and sizing of crushers should . involves the use of M&S(Mine/Mill) ratios as seen in the following formula. chat online

Jaw Crusher - an overview | ScienceDirect Topics

4.2.2 Jaw Crusher Circuits. Primary jaw crushers typically operate in open circuit under dry conditions. Depending on the size reduction required, the primary jaw crushers are followed by secondary and tertiary crushing. The last crusher in the line of operation operates in a closed circuit.

Crushers - All crusher types for your reduction …

Jaw crushers . Jaw crushers are mainly used as primary crushers. Their main purpose is to reduce the material to a small enough size that it can be transported by conveyors to the next crushing stages. As the name suggest, jaw crushers reduce rock and other materials between a fixed and a moving jaw.

Primary size reduction with Jaw Crushers - abmbv.nl

Jaw Crushers 6 selection guide for Jaw Crushers The choice of Jaw Crusher depends primarily on the feed material size and the amount to be crushed. With its compact space-saving de-sign, model BB 51 is often used in laboratories for pre-crushing small amounts of sample with a large feed size. Series BB 100, BB 200 and BB 300

Crusher Reduction Ratio - Mineral Processing & …

As an example, suppose that it is required to make a reduction of 7:1 in two stages of crushers, one a standard gyratory and the other a fine-reduction crusher. We know from our examination of the crushing characteristics of these types that, for equal reduction ratios, the volume-reduction-ratio in the standard gyratory is considerably higher than it is in the fine reduction crusher.

how to calculate jaw crusher reduction ratio

Size reduction equipment is made to crush materials by impact, attrition, shear ... mildly abrasive material and ideal when a large reduction ratio is necessary, ...

Crusher - Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

Jaw crushers - liming

Jaw crushers are mainly used as primary crushers. Their main purpose is to reduce rocks to smaller sizes for the next crushing stages. Jaw crushers are a popular alternative to primary gyratory crushers, since they can process large amounts of hard material efficiently.

Reduction ratio of jaw crusher - frame4frame.nl

Cone Crusher Jaw Crushers size reduction ratio of Chat Online Optimal energy management for a jaw crushing process in deep mines in achieving more energy cost reduction of the primary jaw crushing station while improving undersize fraction or ratio of the ore material F80USC.

(PDF) SIZE REDUCTION BY CRUSHING METHODS

Jaw Crushers have found their extensive app lication for the mid crushing of the va rious ores and large-size materials block in the field of m ining, smelting, building material, highw ay ...

how to calculate jaw crusher reduction ratio

Sep 19, 2012· Jaw crushers offer reduction ratios of up to about 6:1, while cone crushers can reduce material size up to a maximum of 8:1 ratio. The finer the crushing, the smaller the reduction ratio. As a basic rule, jaw crushers are the primary crusher taking the mined aggregate and reducing it to a size that a cone crusher can accept.

jaw crusher reduction ratio - ME Mining Machinery

Jaw crushers minevik. High production and reduction. ® C Series™ jaw crushers have an aggressive motion of the pitman and long stroke in the bottom of the cavity. A larger feed opening increases material intake and ensures that the rocks enter the jaw crusher’s cavity without restrictions.

Jaw Crusher for Mining, Construction and …

DOVE Jaw Crushers provide you with smooth trouble-free operation and long operating life. APPLICATION Jaw Crusher s are ideal for various crushing operations and designed for material size reduction, and widely used in mining & metallurgical, construction, road and railway building, and chemistry industries, etc.

size reduction in jaw crushers - payforwork.nl

Crushers, Pulverizers, Size Reduction MillsDetroit . Detroit Process Machinery buys and sells Crushing, Pulverizing, Granulating and Size Reduction Mills used in the processing industry. We sell machinery used to process raw materials into fine powder. We can provide machines for raw material crushing such as jaw crushers, roll crushers. Get Price

Jaw Crushers For Primary Size Reduction

Jaw crushers primary size reduction retsch jaw crushers are used for the rapid, powerful crushing and precrushing of mediumhard, hard, brittle and tough materials. the variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants.

Jaw Crusher| Eriez Lab Equipment

JAW CRUSHER 150 x 250: L07.001: 150 x 250 (6" x 10") Jaw Crusher with: • 5.5 kW Electrical motor • Starter with overload protection • Cast Iron construction with Mild Steel base frame • V-belt driven with pulley & flywheel guard Standard Guards • Reversible Manganese Steel Jaws Inlet Size: 6" x 10" (150 x 250 mm) Maximum Feed Size: 125 mm

Jaw Crushers | McLanahan

Jaw Crushers. Jaw Crushers are used to reduce the size of many different types of materials in many applications. The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers.