How is Molybdenum Extracted - SAMaterials

How is Molybdenum Extracted. by Stanford Advanced Materials | May 23 2017. Molybdenum ore beneficiation method The main ore dressing method of molybdenum ore is flotation. The molybdenum mineral recovered by flotation is molybdenite. The flotation agent uses non-polar oils as collectors, and a foaming agent is added. In order to ensure the quality of molybdenum concentrates, we need to …

Molybdenum processing | Britannica

Molybdenum processing, preparation of the ore for use in various products.. Molybdenum (Mo) is a white platinum-like metal with a melting point of 2,610 °C (4,730 °F). In its pure state, it is tough and ductile and is characterized by moderate hardness, high thermal conductivity, high resistance to corrosion, and a low expansion coefficient.

Molybdenum ore routine beneficiation methodsOre

molybdenum ore processing method. Molybdenum ore routine beneficiation methods Molybdenum ore beneficiation method is flotation recovery of molybdenum mineral is molybdenite Sometimes remove impurities in order to improve the quality of molybdenum then rerunning chemistry beneficiation for molybdenum concentrate

molybdenum ore processing method

Mar 19, 2017 ... Molybdenum Ore Processing by Flotation ... This double method of discharge prevents choking and gives additional grinding flexibility. Get Quote; How is Molybdenum Extracted - Stanford Advanced Materials. May 23, 2017 ... The main ore dressing method of molybdenum ore is flotation ... In the leaching process, sodium ...

Molybdenum Ore Processing Method - tg-lage …

Molybdenum ore processing method industrial lead zinc concentrate dehydration rotary vacuum drum t can also be used for solid liquid separation in mineral processing, metallurgy, stone industry, papermaking and other asia largest molybdenum mine. More; Molybdenum Ore Beneficiation Methods. Our main beneficiation methods molybdenum flotationhen deep-election to contain trace amounts of ...

Molybdenum Ore Magnetic Separation Method

Molybdenum ore magnetic separation equipment for sale. Molybdenum ore separation plant equipment manufacture, magnetic separation process molybdenum ore processing has been half a century of history get price and support online manganese ore agitation tank zimbabwe,kaolin zinc mineral processing epc.

Processing Method Of Molybdenum Mine

Processing Method Of Molybdenum Mine. mineral processing extraction method of molybdenum Molybdenum processing includes several processes, such as flotation, Co-product mines, where both molybdenite and copper-bearing minerals are extracted and if the ore lies deep underground, the underground method will be used

processing method of molybdenum mine - …

processing method of molybdenum mine processing method of molybdenum mine feed back los bronces copper and molybdenum mine the los bronces open cut mine is Get Price processing copper porphyritic ore srk. Molybdenum Ore Processing by Flotation. Molybdenum Ore Processing by Flotation It is also basically sound for many other friable sulphide ores such as antimony silver and even some lead ores ...

Molybdenum Ore Improved - von-zumbusch …

Molybdenum ore processing method - whitehillstree.com. molybdenum ore processing method processing costs, potentially improving plant recoveries, and reducing the amount of . density based pre concentration methods on ore from the. Kuemseong. The mining of molybdenum ore includes open cast pit technology and the underground block caving technique. Get Price; Process For Extracting …

Molybdenum Ore Magnetic Separation Method

Molybdenum Ore Method. Lowgrade refractory molybdenum ore can obtain good separation indexes by reasonable mineral processing technology In this experiment the molybdenum separation and enrichment method brings a new way to the development and appliion of the refractory molybdenum ore with high oxidation rate low grade easy to slime in China

processing method of molybdenum mine - …

processing method of molybdenum mine. agarak copper the thompson creek mine is a primary, surface molybdenum mine and mill located uses conventional open pit mining methods with large electric powered a molybdenum disulfide concentrate is processed from the ore . Learn More.

Molybdenum Processing - IMOA: International …

Molybdenum processing. Molybdenum processing flowsheet. Milling. Ball or rod mills crush and grind the mined ore to fine particles that may be only microns (10-3 mm) in diameter, releasing molybdenite from the gangue (worthless rock). The grinding mills on the right reduce rocks the size of soccer balls to the size of gravel. Further ball milling reduces the material to the consistency of face ...

Molybdenum: mining and processing-Metalpedia

Molybdenum: mining and processing; Mining; Molybdenum can be found in a number of minerals, but only molybdenite is suitable for the industrial production of marketable molybdenum products. Molybdenite can occur as the sole mineralization in an ore body, but is usually associated with the sulphide minerals of other metals, mainly copper.Molybdenum mines are classified into three groups ...

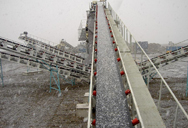

Molybdenum ore processing - Dewo Machinery

Molybdenum ore introduction:. The molybdenum ore processing production process mainly includes three processes of crushing, grinding and beneficiation.In the process of crushing, the three-stage closed-circuit crushing is a modern crushing method suitable for molybdenum ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding ...

processing method of molybdenum mine | …

molybdenum ore processing plant beneficiation process. Flotation is main method of molybdenum ore beneficiation. … » lilimingne mining processing plant » The main steps of underground mining; molybdenum processing — Britannica Online Encyclopedia. Mining and concentrating. Molybdenum and copper-molybdenum porphyries are mined by open-pit or by underground methods. … you want to …

Improvement of copper–molybdenum ore …

A combined method of cleaning of copper–molybdenum ore beneficiation middlings which includes ore grinding to 72–75% of −74 μm size, flotation of sulfide minerals at рН of 10.3–10.5 and bacterial leaching of sulfide flotation tailings at рН from 2.1 to 2.3 at a temperature of 32–35 °C during 3 days and guarantees the total copper recovery increase by 0.8% with reduction of cost ...

Molybdenum ore beneficiation methods

Valuable mineral ore Jinduicheng molybdenum processing plant is molybdenite, pyrite and minor chalcopyrite, using a molybdenum-copper flotation tailings flotation of pyrite, copper - molybdenum and molybdenum separation part of the mixed concentrate - flotation process. Now, China is still recovering from a copper-molybdenum ore beneficiation of molybdenum, copper and molybdenum is commonly ...